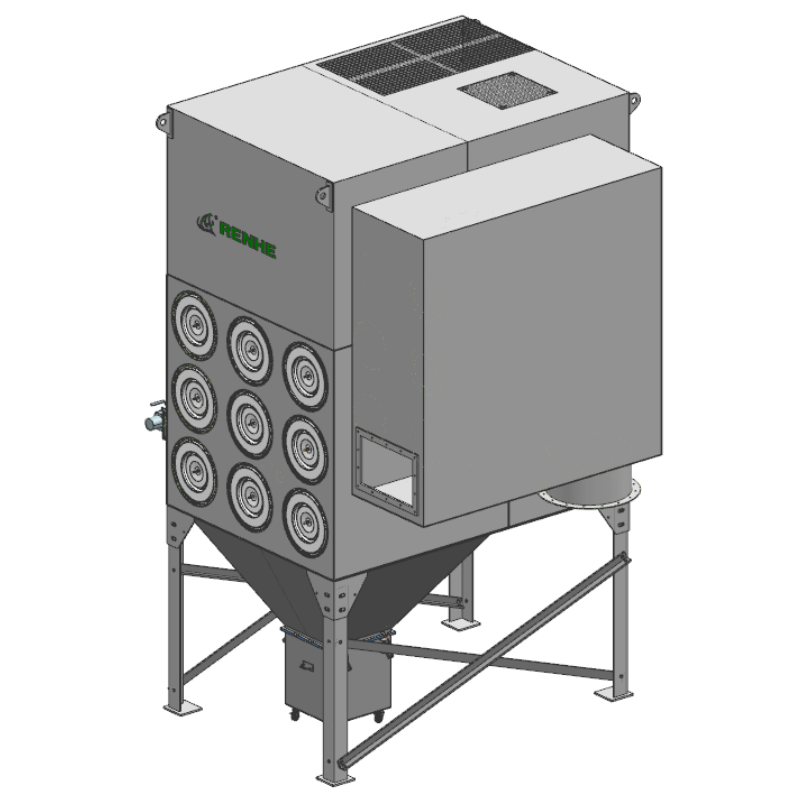

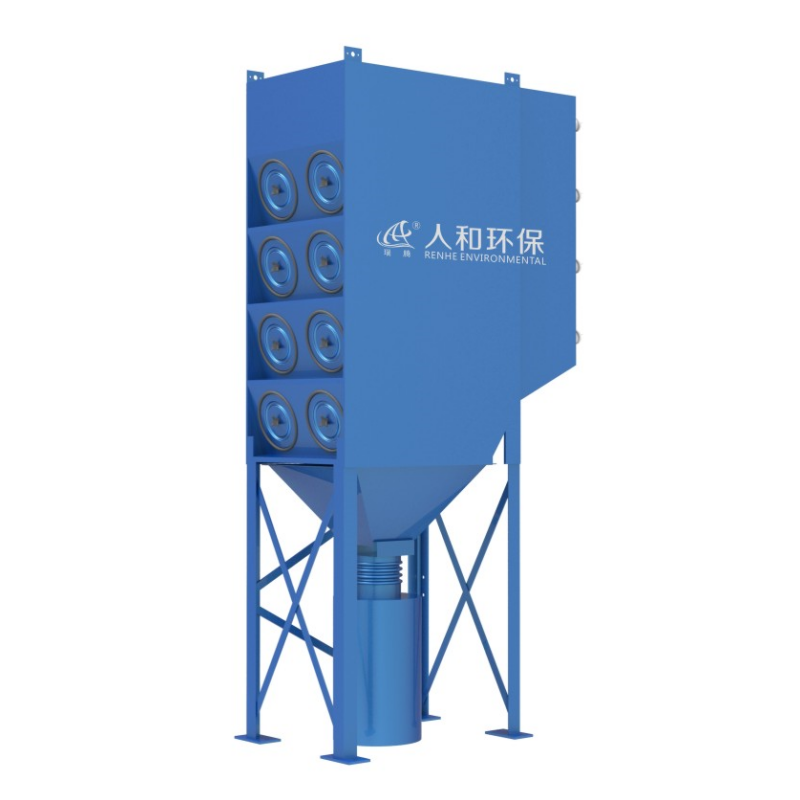

- Overview

- Related Products

HOWIT WORK

Guided by the blower, the dirty air goes insides, then the bigger dust particles sink into the hopper for the sake of the gravity and inertia force. The small size and low density of the dust will be filtered on the surface of filter media by the Brownian diffusion, fiber intercept and other combined effect. Then the filtered airflow into the clean room and is released by the blower. The resistance of the filter cartridge increases with the increasing the dust on the surface of the filter cartridge. When reaching the setting limit, then the tube of the solenoid valve will send out high speed, high pressure flow to do dust-cleaning. The PLC controls the on/off of the pulse valve, when turning on, the air in the manifold will well-proportioned goes into the filter cartridge by the means of the venturi. The instant positive pressure cause a big shake to make the dust falling down into the hopper. The collected dust is discharged into the drum by the discharge valve.

The top row of filter cartridges will start the pulse work firstly, then the next row in turn.

FEATURES

Advanced downflow cartridge distribution and horizontal loaded method, the dust-cleaning efficiency is fairly good during normal working conditions.

There is a anti-abrasion baffle in the dirty air inlet to prent the air hit the cartridge directly to prolong its service life:

015° inclined drawer installation method makes the replacement easy, and no transmission parts inside the body reduces the maintenance work at most.

For ordinary dust, filter cartridge can work a long term and no need to replace frequently compared with the bag filter:

Modular design makes it easy to assemble a bigger one without much

changes to original equipments.

TECHNICAL SPECIFICATION

Model |

Air flow m3/h |

Filter area m2 |

Qty of filter cartridge |

Working resistance Pa |

Filter efficiency % |

Size(H*W*L) mm |

G. weight Kg |

RH/XLC 2-8 Ⅱ |

3300-7500 |

184 |

8 |

Initial resistance 120-250 Working resistance 500-700 Final resistance 1000-1250 |

99.99 |

3175*1016*2159 |

841 |

RH/XLC 3-12 Ⅱ |

5000-11250 |

276 |

12 |

3632*1016*2159 |

1105 |

||

RH/XLC 4-16 Ⅱ |

6600-15000 |

368 |

16 |

4115*1016*2159 |

1164 |

||

RH/XLC 3-24 Ⅱ |

10000-22000 |

552 |

24 |

3632*2032*2159 |

1695 |

||

RH/XLC 4-32 Ⅱ |

13500-30000 |

736 |

32 |

4115*2032*2159 |

2032 |

||

RH/XLC 3-36 Ⅱ |

15000-33500 |

828 |

36 |

3632*3048*2159 |

2377 |

||

RH/XLC 3-48 Ⅱ |

20000-45000 |

1104 |

48 |

3632*4064*2159 |

3136 |

||

RH/XLC 4-48 Ⅱ |

20000-45000 |

1104 |

48 |

4115*3048*2159 |

2859 |

||

RH/XLC 4-64 Ⅱ |

20000-45000 |

1472 |

64 |

4115*4064*2159 |

3700 |

APPLICATION

Different kinds of dry dust, especially the low dust density inlet dust extraction.

Application industries: shipping building, tobacco, machinery casting.

pharmaceutical, steel, petrochemical industry, chemical industry, etc