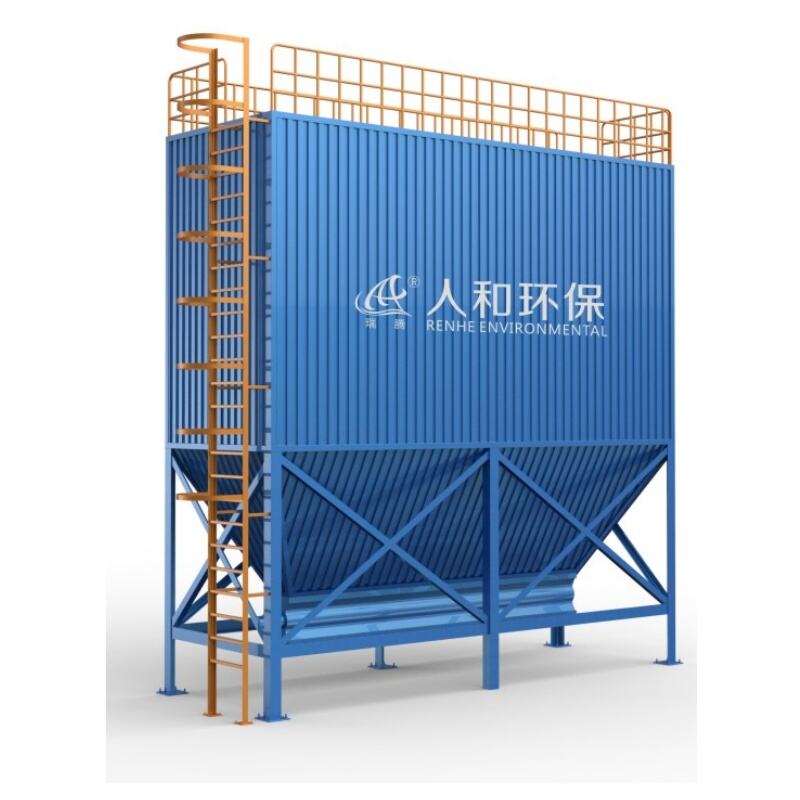

- Overview

- Related Products

HOW IT WORK

Suction by the blower, through the inlet the dirty air is filtered by the bags, the dust drops into the hopper and is discharged through the valve under the effect of the pulse compressed air. The clean air goes out though the blower’s suction.

FEATURE

Different filtering request, you can choose the proper bags, the filter efficiency can be 99.99%.

Working temperature range:-25C-260C for your choice.

The important part of the dust collector is laser cut, high machining precision to ensure the seal ability.

Advanced structure and low operating cost.

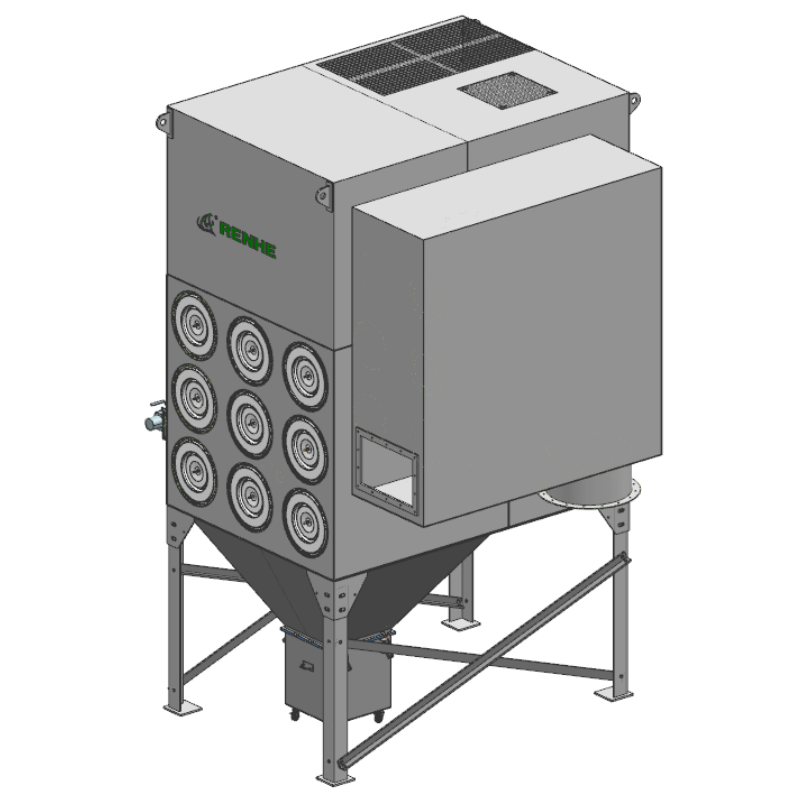

STRUCTURE

RH/DMC dust collector consists of body, hopper, dust discharge units, filter bags, pulse dust-cleaning units(pulse valve and controller),etc.

TECHNICAL SPECIFICATION

Model |

Air flow m3/h |

Filter area m2 |

Qty of filter bags |

Specification of filter bag mm |

Filter efficiency % |

Size(W*L*H) mm |

Qty of pulse valve |

RH/DMC-36 |

3240 |

27 |

36 |

Φ150*2000/Φ120*2000 |

99-99/99 |

1610*1670*4080 |

6 |

RH/DMC-48 |

4320 |

36 |

48 |

2010*1670*4080 |

8 |

||

RH/DMC-60 |

5400 |

45 |

60 |

2410*1670*4080 |

10 |

||

RH/DMC-72 |

6480 |

54 |

72 |

1670*2810*4080 |

12 |

||

RH/DMC-84 |

7560 |

63 |

84 |

3210*1670*4080 |

14 |

||

RH/DMC-96 |

8640 |

72 |

96 |

3610*1670*4080 |

16 |

||

RH/DMC-108 |

9720 |

81 |

108 |

4010*1670*4080 |

18 |

||

RH/DMC-120 |

10800 |

90 |

120 |

4410*1670*4080 |

20 |

APPLICATION

Density of the dust 15g/m3 under the working temperature less than260℃Application: Cement, graphite, silicon powder, casting, grain, chemical industry, tobacco, etc. Post treatment method of filter bags Hi-temperature, Membrane, Antistatic, water & oil resistance, etc.