- Overview

- Related Products

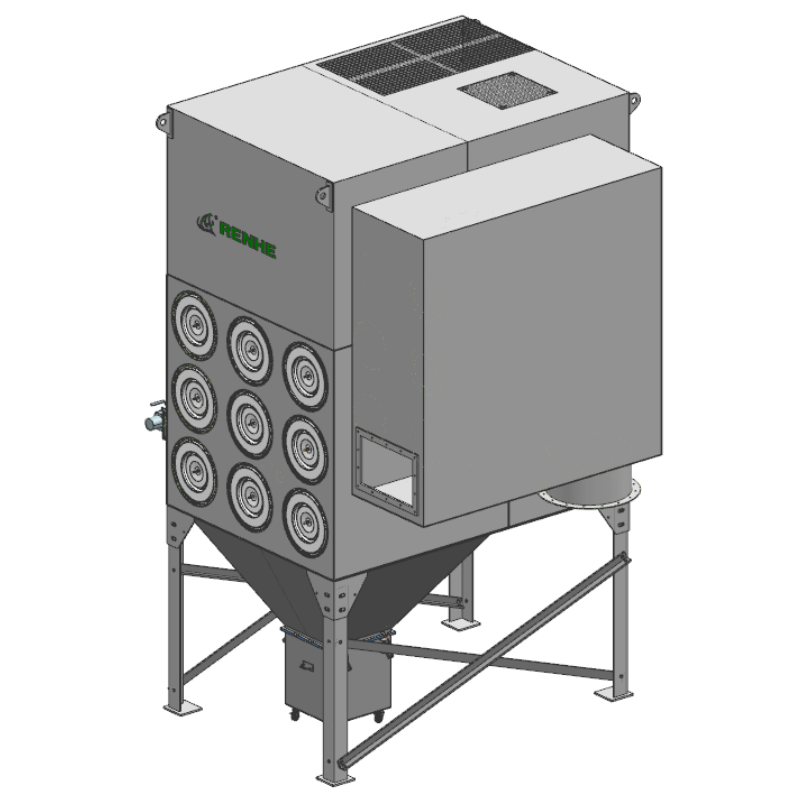

HOW IT WORK

The suction of the blower under the table makes sanding area under the condition of negative pressure. The polishing and cutting dust is suctioned into the Filter Cartridge and the discharges the clean air. If the density of the dust is high, just starting the pulse dust-cleaning and cleaning up the drawer regularly.

FEATURES

Air deflector at the inlet of the table prevents the dirty air directly hitting the filter elements to prolong the service life of the filter elements.

The bower type is centrifugal with low noise level, high efficiency and working steadily.

To prevent the noise pollution, the equipment is de-noised.

The table is polishing and dust collecting from the source at same time.

Compact structure, less footprint and suitable for double-table and multi-table.

According to the dust, choosing the proper filter media.

Long service life, working steadily and easy replacing.

Exhaust inlets at the front side, under and above the table will efficiently control the dust flying.

Automatic pulse dust-cleaning will ensure the equipments working well

Drawer is quick and easy to dust cleaning up.

TECHNICAL SPECIFICATION

Model |

Air flow m3/h |

Power Kw |

Resistance loss Pa |

Size(L*W*H) mm |

Weight Kg |

Load of table Kg |

RH/DMC-36 |

2000 |

3.0 |

180 |

1700*960*1720 |

300 |

100 |

RH/DMC-48 |

2500 |

4.0 |

180 |

1800*960*1720 |

400 |

150 |

RH/DMC-60 |

3000 |

5.5 |

180 |

1900*960*1720 |

500 |

200 |

APPLICATION

Welding, polishing, grinding, deburring, cutting, etc.

Building material, FRP metallurgy, chemical industry, electric power, machinery manufacturing, casting and other industries products processing.