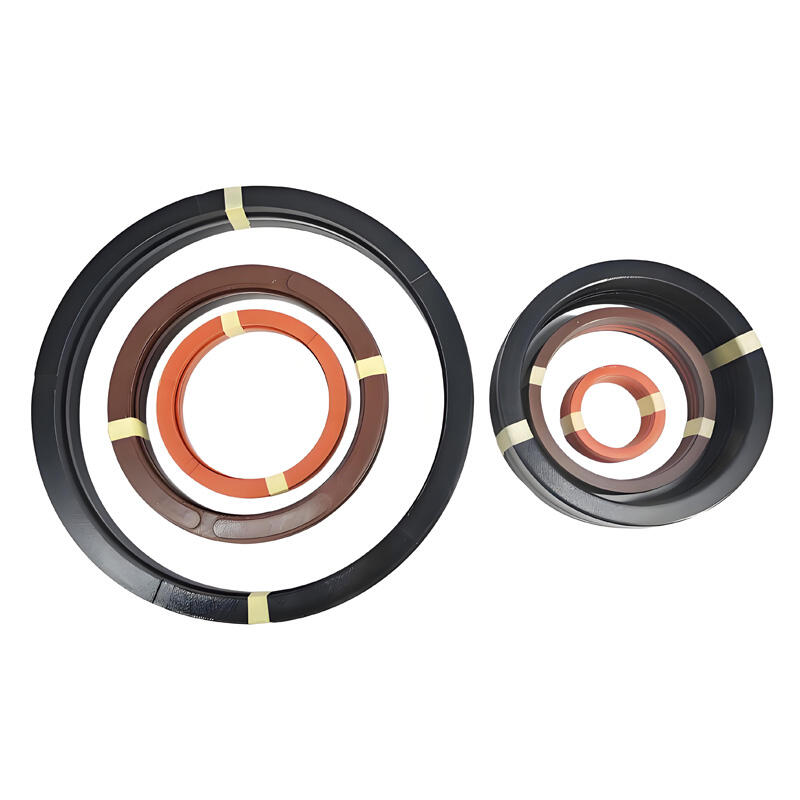

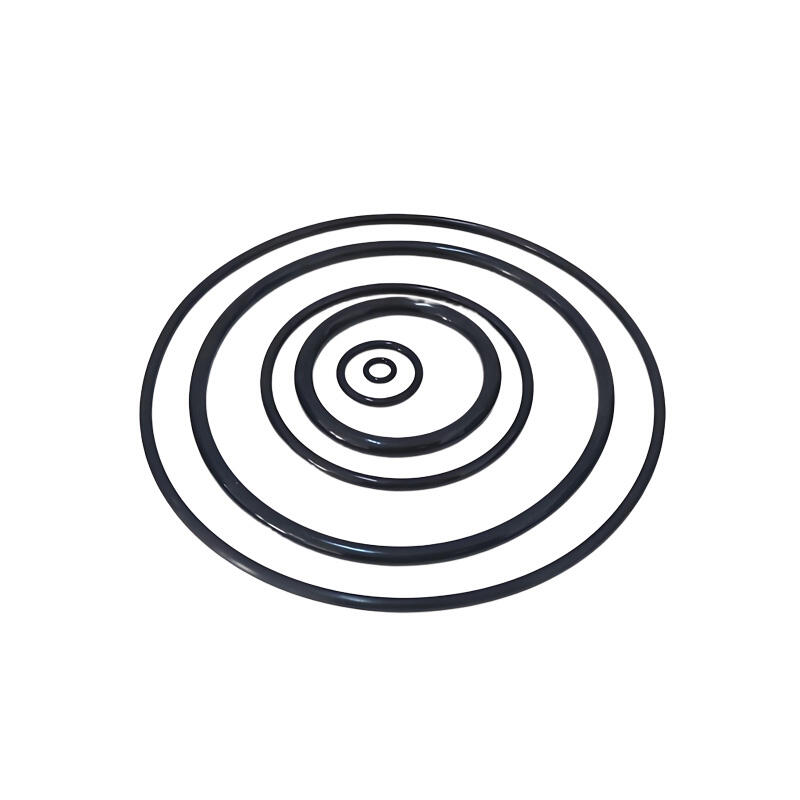

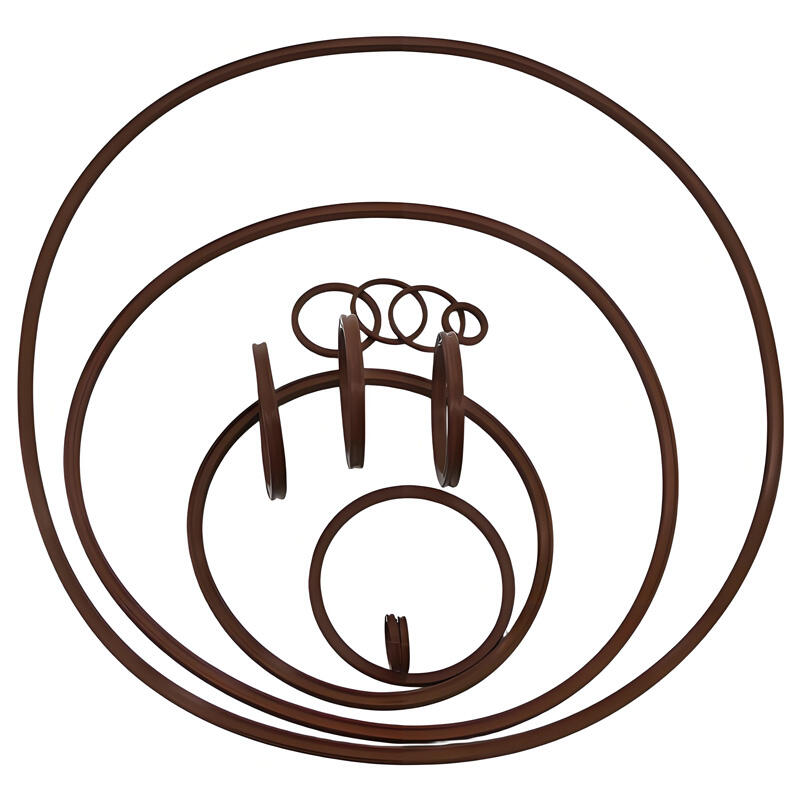

heavy duty truck seal

Heavy duty truck seals are essential components designed to maintain the integrity and performance of commercial vehicles. These specialized sealing solutions are engineered to withstand extreme conditions, providing reliable protection against contaminants, moisture, and pressure differentials in various truck systems. The seals are manufactured using advanced elastomer compounds and reinforced materials that ensure durability under high-stress applications. They play a crucial role in protecting vital components such as wheel ends, transmission systems, and engine compartments from environmental factors and operational stress. The design incorporates precise geometries and material selections that accommodate the dynamic movements and thermal variations experienced in heavy duty trucking applications. These seals feature innovative lip designs that maintain consistent contact pressure, ensuring optimal sealing performance throughout their service life. They are specifically engineered to handle the increased loads, speeds, and operating temperatures common in commercial transport vehicles. The implementation of these seals helps prevent lubricant leakage, extends component life, and maintains system efficiency, ultimately contributing to reduced maintenance costs and improved vehicle reliability. Advanced manufacturing processes ensure consistent quality and dimensional accuracy, making these seals suitable for standardized replacement parts across various truck models and applications.